Understanding Titanium Nuts Manufacturers: The Backbone of Quality Sporting Goods and Outdoor Gear

In the realm of sporting goods, outdoor gear, and bicycles, the importance of durable and lightweight materials cannot be overstated. One material that has gained immense popularity in recent years is titanium. It is renowned for its strength, corrosion resistance, and lightweight characteristics. At the heart of manufacturing high-quality titanium components are the titanium nuts manufacturers. This article delves into the pivotal role these manufacturers play in the industry and explores the advantages of titanium in various applications.

The Significance of Titanium Nuts in Modern Manufacturing

Titanium nuts serve as crucial components in various applications, providing essential fastening capabilities in sporting goods, outdoor gear, and bicycles. Here’s why they are significant:

- Lightweight Properties: Titanium is significantly lighter than steel, making it ideal for products designed for performance and portability.

- Strength and Durability: The tensile strength of titanium surpasses that of steel, which ensures that components can withstand substantial stress and strain.

- Corrosion Resistance: Titanium does not rust and is resistant to many corrosive environments, ensuring longevity in outdoor applications.

- Biocompatibility: Titanium is non-toxic and is widely used in applications that require interaction with the human body, such as in certain sporting goods and medical gear.

The Role of Titanium Nuts Manufacturers

Titanium nuts manufacturers play an integral role in the supply chain of outdoor equipment, ensuring that end-products maintain the highest standards of quality and performance. Here are several key functions they perform:

1. Material Sourcing

Manufacturers start with sourcing high-grade titanium. The purity of the titanium impacts the ultimate quality of the nuts produced. Premium-grade titanium ensures superior strength and resistance to corrosion.

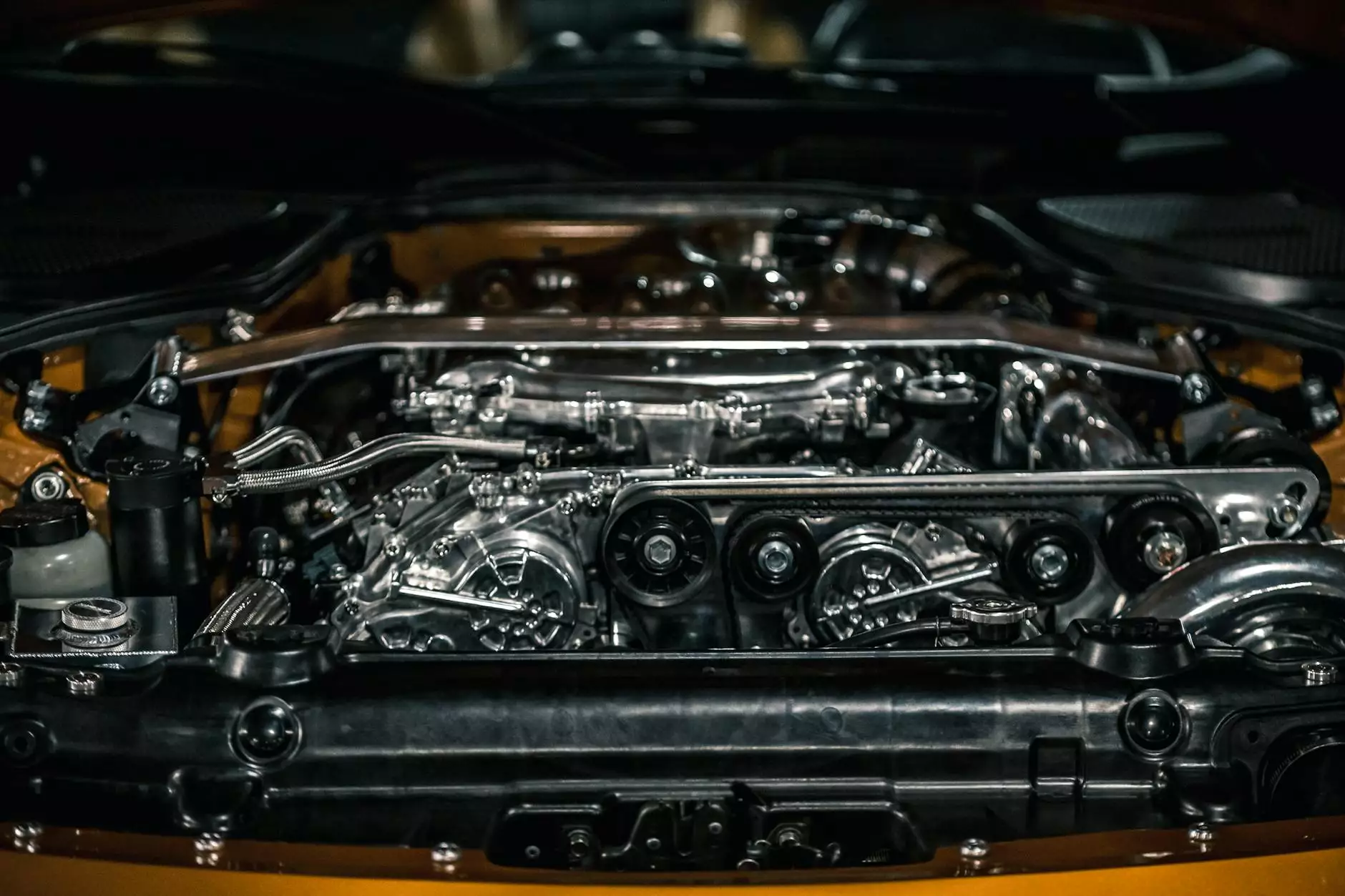

2. Precision Engineering

Utilizing advanced manufacturing processes such as CNC machining and forging, titanium nuts are crafted with precision. This not only ensures that they fit properly but also optimizes their performance in various applications.

3. Quality Control

Stringent quality control measures are pivotal in the manufacturing process. Manufacturers rigorously test the strength and durability of the nuts, ensuring they meet industry standards and customer expectations.

4. Customization Options

Many titanium nuts manufacturers offer customized solutions to meet the specific needs of their clients, whether in size, strength, or finishing options. This flexibility is essential for businesses looking to differentiate their products in the competitive market.

Advantages of Titanium Nuts in Sporting Goods and Outdoor Gear

When it comes to sporting goods and outdoor gear, the advantages of using titanium nuts are manifold:

1. Enhanced Performance

By incorporating titanium nuts, products become lighter while maintaining structural integrity. Athletes and outdoor enthusiasts benefit from equipment that enhances their performance.

2. Increased Lifespan

The corrosion resistance of titanium means that nuts will not degrade over time, even with exposure to extreme weather conditions or moisture, ultimately leading to increased product lifespan.

3. Improved Aesthetics

Titanium nuts can be anodized to produce a range of colors while maintaining their excellent properties, allowing manufacturers to offer visually appealing products.

4. Sustainability

Titanium is a recyclable material, making it an environmentally friendly choice. By choosing titanium nuts, manufacturers adopt more sustainable practices, attracting eco-conscious consumers.

Innovation in Titanium Manufacturing

The field of titanium manufacturing is constantly evolving, with innovations that promise to change the landscape further:

1. 3D Printing

Advancements in 3D printing technology are enabling manufacturers to create complex titanium components with reduced waste and increased customization. This technology is revolutionizing how titanium nuts can be produced.

2. Alloy Development

New titanium alloys are being developed to improve performance in specific applications. Manufacturers can create titanium nuts that are tailored to withstand unique stresses and conditions found in extreme sports.

3. Automated Production Processes

Automation is streamlining production, reducing labor costs, and enhancing precision. These advancements contribute to a lower price point for high-quality titanium nuts without sacrificing quality.

Finding the Right Titanium Nuts Manufacturers

For companies looking to source titanium nuts, it’s crucial to choose the right manufacturer. Here are some factors to consider:

1. Industry Experience

Look for manufacturers with extensive experience in the field. Established companies have likely dealt with various challenges and can provide reliable products.

2. Reputation

Research customer reviews and case studies. A reputable manufacturer will have positive feedback on their products and services.

3. Certifications

Ensure that the manufacturer has the necessary quality certifications, such as ISO, which indicates their commitment to maintaining high standards.

4. Customer Support

Choose a manufacturer that provides excellent customer service, as effective communication can simplify the production process and ensure your requirements are met.

Conclusion: The Future of Titanium Nuts in Sporting Goods and Outdoor Gear

As the demand for high-performance, durable, and lightweight materials continues to grow, the role of titanium nuts manufacturers becomes more critical. With advancements in manufacturing processes, material science, and sustainability practices, titanium is poised to remain a top choice for manufacturers in the sporting goods and outdoor gear industries. By understanding the advantages and innovations within the sector, companies can leverage the expertise of titanium nuts manufacturers to enhance their product offerings and meet the evolving needs of consumers.

Investing in titanium nuts not only elevates the quality of sporting goods and outdoor gear but also aligns businesses with the growing trend towards sustainable manufacturing. As we move forward, embracing the innovations and benefits that titanium nuts offer will be essential for manufacturers aiming for growth and excellence in a competitive market.