Why Choose a China CNC Parts Factory for Your Metal Fabrication Needs?

In today’s fast-paced global economy, businesses are constantly seeking ways to optimize their production processes and enhance their product offerings. One effective way to achieve this is by partnering with a China CNC parts factory. These factories specialize in the precise and efficient machining of components that meet the high demands of various industries, including automotive, aerospace, electronics, and more. In this article, we will delve deep into the many benefits of working with a China CNC parts factory and how such a partnership can contribute to your business success.

The Rise of CNC Machining in China

China has become a powerhouse in the manufacturing sector, particularly in the field of CNC (Computer Numerical Control) machining. With a strong emphasis on innovation and efficiency, Chinese CNC parts factories have revolutionized the way metal components are produced. Here are several compelling reasons why China manufacturing is at the forefront:

1. Economies of Scale

A major advantage of sourcing from a China CNC parts factory is the economies of scale. With a large number of manufacturers competing in the market, these factories can produce components at a significantly lower cost. This is due to:

- High production volumes: Chinese factories typically operate on a larger scale, allowing them to reduce per-unit costs.

- Advanced technology: Many factories invest in the latest CNC technologies, enabling more efficient production.

- Lower labor costs: Competitive labor costs in China add to the overall affordability of manufacturing.

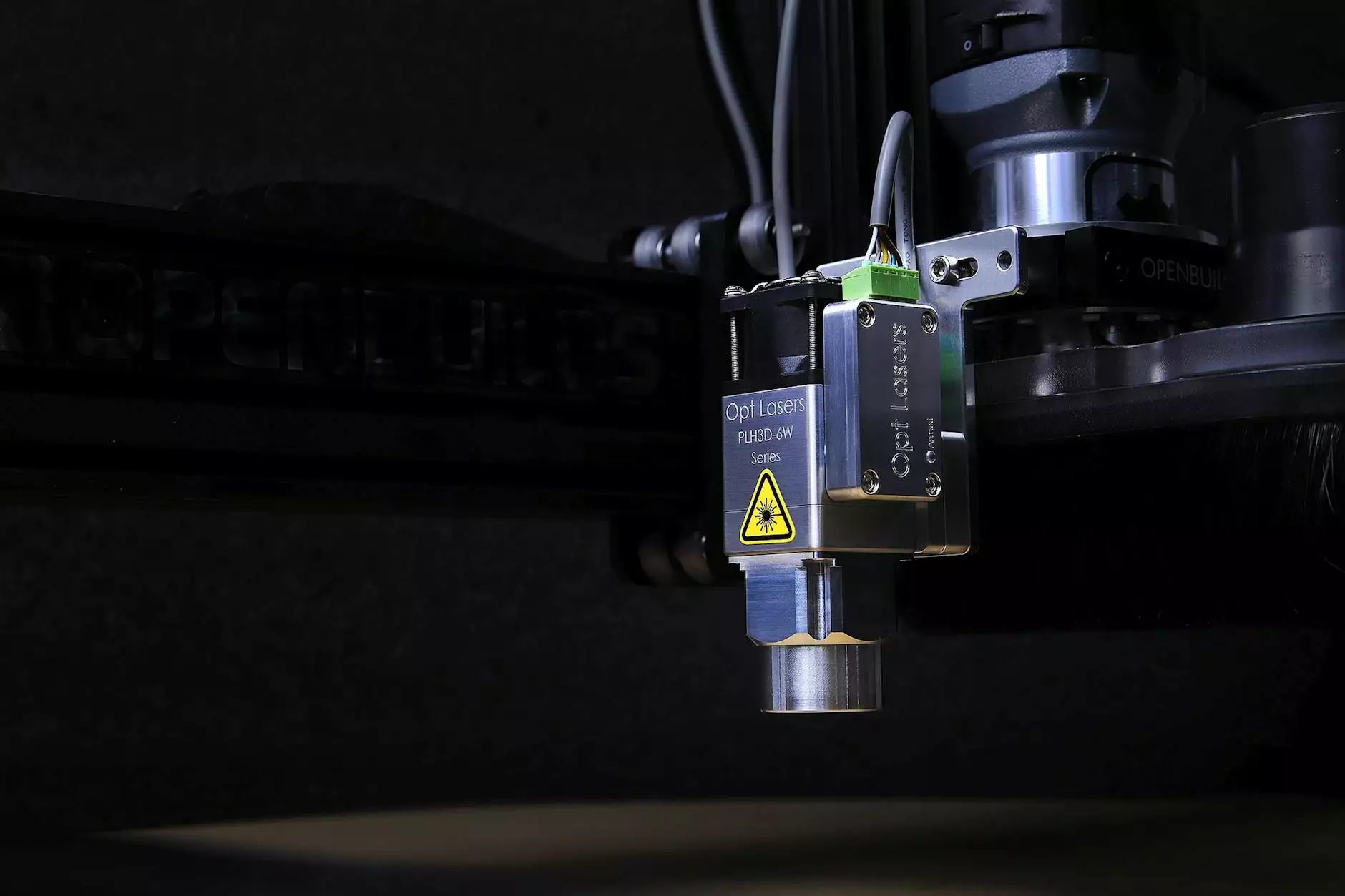

2. Access to Advanced Manufacturing Technologies

Chinese CNC parts factories are known for their commitment to using cutting-edge technology in manufacturing. This access to advanced machinery allows for a range of benefits, including:

- Precision and accuracy: CNC machines provide exceptional precision, ensuring that parts meet stringent specifications.

- Diverse capabilities: These factories often possess the ability to produce complex geometries and a wide range of materials.

- Rapid prototyping: Advanced technologies enable swift prototyping services, expediting product development timelines.

Quality Assurance in Chinese Manufacturing

When dealing with a China CNC parts factory, quality assurance is of utmost importance. Many factories adhere to international standards such as ISO 9001, which ensures a high level of quality in their manufacturing processes. Here’s how they maintain quality:

1. Strict Quality Control Measures

Chinese manufacturers implement rigorous quality control (QC) measures throughout the production process. This includes:

- In-process inspections: Continuous monitoring during production helps identify and rectify issues in real-time.

- Final inspections: Comprehensive testing of finished products ensures they meet customer specifications and industry standards.

- Skilled workforce: In many cases, workers are extensively trained to maintain high-quality outputs.

Customization and Flexibility

One of the standout features of partnering with a China CNC parts factory is their ability to provide tailored solutions. This customization is essential for businesses looking to create unique products. Here’s how they achieve flexibility:

1. Tailored Manufacturing Solutions

Manufacturers in China are adept at producing custom parts based on clients’ specific requirements. They offer:

- Material selection: A wide range of materials can be utilized, from aluminum and steel to specialized alloys.

- Design modifications: Engineers can provide insights and revisions to optimize product design.

- Variable production runs: Whether a business needs a small batch or mass production, Chinese factories can scale their operations accordingly.

2. Quick Turnaround Times

In the competitive landscape of manufacturing, speed to market is crucial. China CNC parts factories are capable of:

- Rapid production processes: Their advanced technology and large workforce enable quick turnaround on orders.

- Efficient logistics: Many manufacturers have established supply chains that facilitate timely deliveries, both domestically and internationally.

Exploring the Short- and Long-term Cost Benefits

Investing in a China CNC parts factory can yield significant cost advantages. Here’s how:

1. Lower Production Costs

By leveraging the lower operational costs in China, businesses can save on:

- Material costs: Competitive pricing for raw materials due to large-scale sourcing.

- Labor costs: The cost advantage of labor in China can lead to overall lower production expenses.

- Overheads: Many factories offer lower overhead charges than manufacturers in other regions.

2. Long-term Partnerships and Reduced Costs

Over time, forming a longstanding relationship with a factory can lead to:

- Volume discounts: Consistent orders can qualify businesses for significant discounts.

- Improved communication: A solid partnership leads to better understanding and collaboration, reducing costs associated with errors.

- Innovative solutions: Long-term partnerships often yield creative approaches to reduce manufacturing costs further.

Navigating Challenges When Choosing a China CNC Parts Factory

While the advantages of working with Chinese manufacturers are compelling, businesses must also be aware of potential challenges and how to mitigate them:

1. Language and Cultural Barriers

Effective communication is crucial in any business relationship. Navigating language and cultural differences can be challenging, but these can be addressed by:

- Hiring local representatives: Employing local agents can help bridge the communication gap.

- Utilizing technology: Tools like translation software can facilitate better communication.

- Clear documentation: Providing detailed specifications and drawings reduces misunderstandings.

2. Quality and Compliance Concerns

Ensuring consistent quality and adherence to international standards is essential. Businesses can overcome these concerns by:

- Conducting audits: Regularly auditing the factory can ensure compliance with quality standards.

- Using third-party inspectors: Hiring independent inspectors can verify product quality before shipping.

- Building quality checks into contracts: Clearly outlining quality expectations can foster better compliance.

Conclusion: The Future of Metal Fabrication with China CNC Parts Factories

The China CNC parts factory landscape offers unparalleled advantages for businesses seeking high-quality metal fabrication solutions. The combination of cost-efficiency, advanced technology, and custom capabilities positions these manufacturers as key players in the global market. By carefully selecting a factory that aligns with your quality expectations and forging a robust partnership, you can leverage these benefits to enhance your product offerings and drive business growth.

In conclusion, as the metal fabrication industry continues to evolve, harnessing the strengths of China CNC parts factories can be a game-changer for your business strategy. Embrace the opportunities presented by these manufacturers to differentiate your brand and achieve long-term success in your industry.